Bio Film

Bio Film

SURFACE OF TEFLON® FIGHT BIOFILM BUILD UP

Surfaces of Teflon® resist the onset of biological films because Teflon® is not easily wetted and is not subject to biological or chemical attack. Bacteria are too large to gain a hiding place on the smooth surface of Teflon®. Data reported by the BioProcess Technical Institute, University of Minnesota, shows that accumulated biofilm is far easier to remove from Teflon® than from stainless steel and glass. With easier cleaning, there’s a smaller volume of solution to dispose of, an environmental benefit.

Biofilm Removal, Percent, in Virtually Quiescent Dilute Sodium Hypochlorite [As reported by the BioProcess Technical Institute, University of Minnesota]

|

Commercial Substrate |

K.pneumonia, % |

S.Choleraisuis, % |

E.Coli, % |

|

Stainless Steel (elec. polished) |

67 |

25 |

56 |

|

Polypropylene |

67 |

75 |

75 |

|

Borosilicate Glass |

89 |

0 |

0 |

|

Silicone-Coated Glass |

89 |

89 |

78 |

|

Polyvinylidene Fluoride |

89 |

89 |

89 |

|

Teflon®PFA |

99 |

99 |

98 |

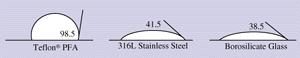

Contact angles in degrees with water show Teflon® is far less wettable than stainless steel or glass.

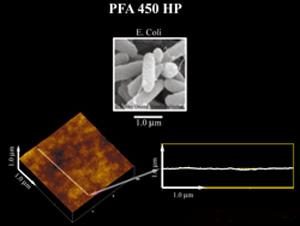

E.coli and other bacteria are too large to lodge in tiny asperities on smooth, nonreactive surfaces of Teflon® PFA HP.

EMPICO COATING SDN BHD

Source: Blackman, Tassi, Metcalfe

(Profile of the inside surface of Teflon® PFA pipe)

(Profile of the inside surface of Teflon® PFA pipe)

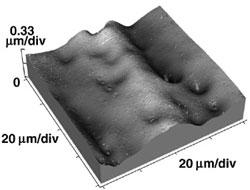

Electropolished (10RA) stainless steel can have pits that harbor biofilm and is much more wettable by aqueous media than Teflon®.